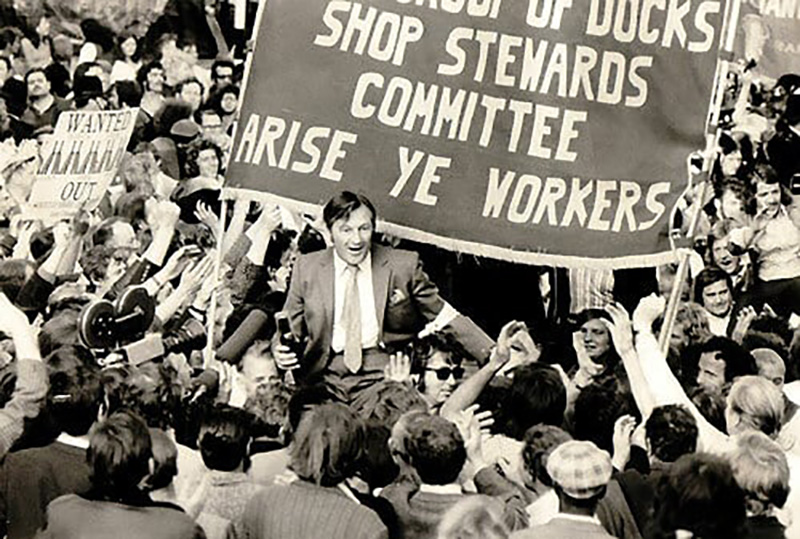

For the best part of forty years, I was a Trade Union Representative. I was a rep in many different workplaces and have witnessed many hilarious incidents and, unfortunately, some tragic situations too. These memories are all part of my great career as a trade unionist.

Part 2: The Quality Circle

In the 60s and 70s, there was a distinct difference between ‘us’ (the workers) and ‘them’ (the shirkers), but this began to erode from the early 80s onwards. The anti-trade union legislation brought in by Margaret Thatcher’s government, aided and abetted by the actions of the Harold Wilson Government of 1966 – 1970, who had put forward a white paper entitled “In Place of Strife” in 1969. Although not enacted, it became a blueprint for Thatcher’s oppression and she knew it would be supported by the Labour Party, as well as the majority of trade union leaders, who wanted to keep their members in check every bit as much as the stuffed shirts in Westminster.

It shows that, even then, the Labour Party was incapable of supporting the working class. They are and have always been indisputably in the ‘them’ camp.

When the Tories were elected in 1979, the ‘thems’ were now on a roll. The introduction of ‘new management techniques’ from Japan was a favourite amongst the capitalist class, with their Quality Circles and Kaisen groups ready to undermine the role of the trade unions in industry by direct fraternisation of the workforce in dealing with problems, thereby bypassing both the elected union officials and the agreed negotiation machineries.

The rank and file were totally opposed to these changes, but the management always liked to blow smoke up the backsides of certain people who they knew wouldn’t be in a union were it not for the closed shop and these wretched creatures liked to undermine the shop stewards at every opportunity. Even though these people are union members and workers, they are not part of ‘us’.

In 1985, the disgraceful Amalgamated Engineering Union (which was to merge with the even more contemptible and despised Electrical, Engineering, Telecommunications and Plumbers’ Union to become the Amalgamated Engineering and Electrical Union) entered into an agreement with Nissan in Sunderland to have a single union site, unprecedented in British industry, with a fully flexible workforce.

The site was opened in 1986, but its construction began in November 1984 on land that was sold to Nissan as agricultural (and so less expensive) land. The work started by our old friend Sir Robert McAlpine – he of the blacklisting of building workers in the 1970s fame.

The methods used by Nissan were as previously mentioned, Kaizen, ‘Just In Time’ and job rotation.

Kaizen is a business philosophy of continuous improvement in every department of a factory by what are known as ‘Kaizen Groups’: Under Kaizen, there is no need for shop stewards and the activity and militancy of trade unions is stifled. ‘Just In Time’ is the application of the minimum amount of resources (space, time, materials and workers) to production. Job rotation means that a worker should be competent in three jobs and at least three people should be capable of doing each job. The management maintain that regular rotation of jobs prevents boredom, but it’s main purpose is to prevent demarcation of roles and functions.

I had discussions with the convenors at the Vauxhall car plant in Ellesmere Port, who had visited Japan to study these methods and had formulated a model agreement. We as a union branch committee decided to try to negotiate an agreement before these things were forced upon us, as we knew our full time off-site officials (the ‘thems’) would capitulate and we would all end up high and dry.

The company were determined that they wanted Quality Circles (local worker forums designed to circumvent negotiation machineries and local agreements) and the branch’s stance was that they could have these Quality Circles but nothing else. There would be no single union agreements, no Kaizen and no sweetheart deals made. The agreement stated that the QCs could put forward suggestions as long as they didn’t discuss anything that should be discussed by shop stewards through the agreed negotiation machinery.

I also had the veto on any suggestion proposed for discussion by the QCs by any section under the control of the Transport and General Workers Union if I believed it undermined the role of the shop stewards.

The ‘us’ and ‘them’ still prevailed at this time and there was no mingling of roles. It worked well as in the end the QC members got fed up with their suggestions being vetoed by me. It was carried at branch level that these groups were a waste of time and nobody should be involved in them. The company had persevered with it for a year and finally it was a failure and died a death.

On-site union officials have to be continually vigilant as there are always some people who hate the union and try to undermine it. Believe that your members are right 100% of the time and that management is always wrong. You won’t be far wrong: That’s the “Us and them” mentality

The modern union bureaucracies, the levels above the Branch Secretary and conveynor level is useless to further the aims of the working class. The process for change is too long, too slow and too bureaucratic and that is why most problems, in my day, never went above site level.

We called meetings, we recommended action and we took the lead from the shop floor. It can be done now if people stand in solidarity, but it is much more difficult. However, as long as workers have a class consciousness and understand that ‘Us and them’ still exists, there is still hope for the future.

Leave a comment